design & planning

Every project starts with listening - understanding the client’s needs, vision, and site constraints. We begin by assessing the project in context: reviewing the brief, evaluating the site, and identifying any key planning criteria or design parameters that might shape the proposals.

Where appropriate, we’ll carry out a feasibility study to test what’s realistically achievable, both in terms of space and planning, and to inform early decisions on layout, orientation, and massing. From there, we’ll develop an initial design and work closely with the client to refine it, ensuring it meets their aspirations and budget.

We can provide guidance on costings from an early stage, and where planning consent is required, we can prepare supporting information and submit an application in collaboration with our planning consultant. This means we’re able to offer a full architectural service through to planning approval, and beyond, if required.

Once planning is secured, we shift focus to the detailed design. This is where we fine-tune the specification, layout and finishes. We draw on our established range of options, developed to ensure performance, simplify the process, and keep costs under control, but we can also accommodate bespoke elements where needed. Any custom design work outside of the standard scope is charged at an agreed hourly rate.

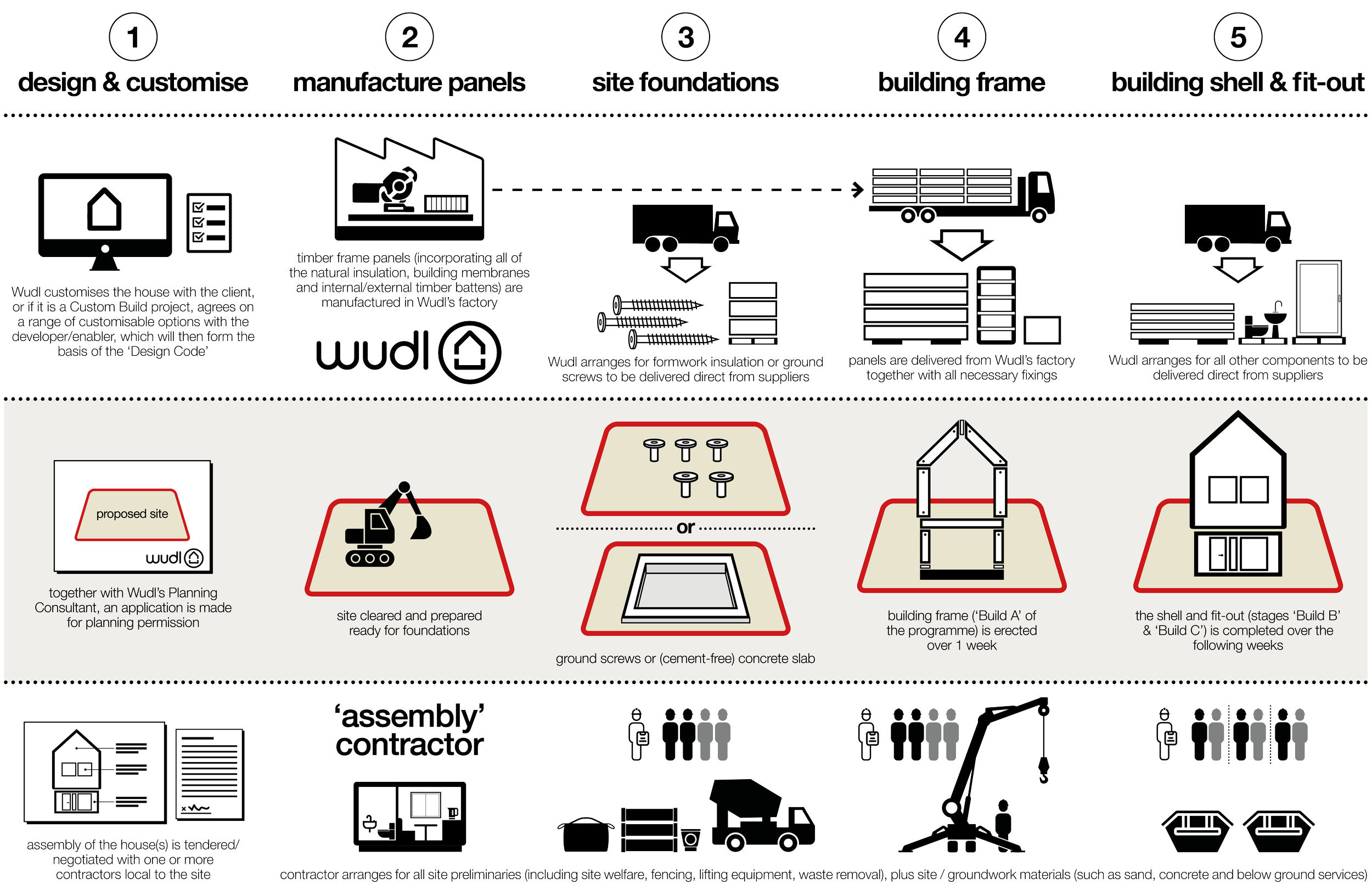

the manufacture & build process

At Wudl, we design and manufacture the complete building system in our factory. This includes all the key structural components - walls, floors, roof panels, and other essential parts of the building. We carefully source and purchase the materials and components to ensure consistent quality, sustainability, and performance.

Once manufactured, the building system is transported to the site and assembled by an assembly contractor. This contractor works under a JCT (Joint Contracts Tribunal) contract, which sets out a fixed price and timescale, giving you clarity and confidence in your project’s delivery.

The assembly contractor is responsible for:

Assembling the building system on site

Sourcing some site-specific materials, like gravel, low-carbon concrete and various site materials, which are often best purchased locally

Managing site preliminaries, including site welfare facilities, lifting equipment, tool hire, and waste removal

We coordinate the entire process, working closely with you and the assembly contractor to ensure a smooth handover from design to manufacture to on-site assembly. Our role is to make the journey from concept to completion as straightforward as possible, providing support at every step.

If you’d like to learn more about how we can help bring your project to life, please get in touch… we’d be delighted to discuss it with you.

full professional services

We offer a complete range of professional services to support the design, manufacture, and delivery of sustainable buildings, including full turn-key solutions. While we don’t directly assemble our buildings on site, we oversee all construction work, carry out inspections, and sign off completed projects to ensure everything meets our high standards.

Our services include:

Bespoke architectural design

Customisation of layouts, finishes, and specifications

Passivhaus design and detailing

Site feasibility studies and assessments

Masterplanning and development frameworks

Town Planning services (in collaboration with our planning consultant)

Design Codes and Plot Passports for Custom Build projects

Off-site manufacturing of our prefabricated timber panel system

Procurement of materials, components, and building systems

Assembly drawings and construction method statements

Contract administration and project coordination

On-site inspections and quality assurance

Final certification and project sign-off

Support with third-party certification (e.g. Passivhaus, SAP) via trusted consultants

We also work with a reliable network of professionals to provide:

Structural and civil engineering services

Mechanical and electrical services design

Energy strategy and low-carbon systems

Landscape and external works design

Biodiversity Net Gain (BNG) assessments and ecology services

Quantity surveying and cost consultancy

Life Cycle Analysis and sustainability reporting

Whether you’re a homeowner, developer, community organisation or housing provider, we can tailor our services to suit your needs at every stage, from initial brief through to finished building.

plus training & knowledge sharing

Alongside our design and construction work, we offer training and CPD sessions through our not-for-profit organisation, Fabric CIC. These workshops focus on sustainable design and construction, Modern Methods of Construction (MMC), low-carbon retrofit, and Carbon Literacy — all increasingly vital in meeting today’s housing and climate challenges.

Our sessions are ideal for housing providers, local authorities, developers, educators, and community groups wanting to deepen their understanding of low-energy building principles. Whether you’re new to terms like airtightness, thermal bridging, and embodied carbon, or looking to gain a practical understanding of off-site manufacture, our workshops offer a solid and engaging introduction.

Most sessions are held at our modular building factory in central Manchester, just 10 minutes’ walk from Piccadilly station, where participants can see sustainable materials, building systems, and our prefabricated panel line in action. We also deliver bespoke talks and visits tailored to specific audiences — from short drop-in visits to full-day immersive sessions.

By demystifying sustainable construction and promoting hands-on learning, our training aims to address the urgent skills shortage across the industry, while highlighting the exciting opportunities this sector holds for future careers.

Find out more at www.fabric-cic.org